In the field of Lean Project Management, methods and tools are crucial to optimize processes and reduce waste. You now have the opportunity to learn about five essential Lean Tools that can help you make your daily work more effective. These tools originate from the time of Toyota and are especially important in factory-oriented environments. But don't be deceived: even in today's digital world, these approaches can be of immense value.

Main Insights

- Lean Tools help optimize processes and eliminate waste.

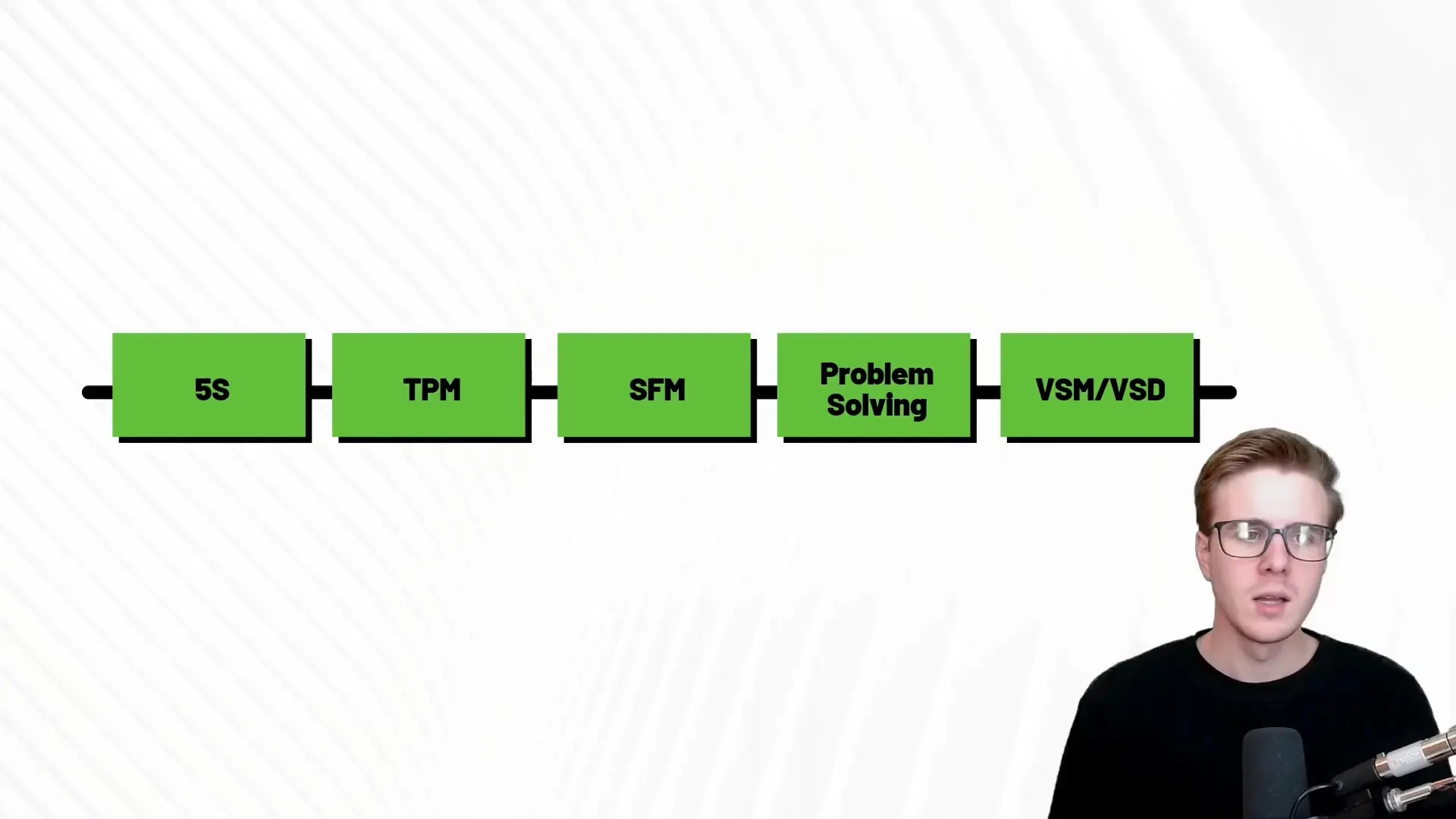

- The main tools are 5S, TPM, SFM, Problem Solving, and Value Stream Mapping (VSM).

- A clean, structured work environment is the foundation for effective work.

- Continuous improvement is the key to success.

Step-by-Step Guide

1. Understanding the 5S Methodology

The 5S Methodology consists of five terms, all starting with the letter S. These will help you optimize your workspace.

- Sort: Start by getting rid of unnecessary items. This can be relevant in both the office and the factory. By decluttering paperwork and other unnecessary materials, you create space for important things.

- Set in order: The remaining materials should now be organized. Ensure that everything has its place and can be quickly found. Clear organization makes it easier for you to access the necessary documents.

- Shine: This is about refreshing your workspace. A clean environment not only promotes productivity but also boosts motivation.

- Standardize: All employees should follow a consistent folder structure and work method. This way, everyone knows where to find which information.

- Sustain (Self-discipline): This step focuses on continuous improvement. It is important that all parties adhere to these standards and continue to look for optimization possibilities.

2. Understanding TPM (Total Productive Management)

TPM is a comprehensive approach to implementing continuous improvement processes in company structures. The goal is to avoid downtime and increase efficiency.

Create an action plan aimed at analyzing and optimizing all processes in the company. This ensures that something is always in motion, and no valuable time is lost.

3. Implementing SFM (Shop Floor Management)

Shop Floor Management aims to improve leadership and management culture.

Promote collaboration between employees and managers. Schedule regular meetings to enhance the exchange of ideas and information. This not only increases efficiency but also boosts employee satisfaction.

4. Establishing a Problem Solving Culture

Problem Solving, or the problem-solving culture, is crucial for fostering responsibility among employees.

Create an environment where employees are encouraged to address problems independently and find solutions. This not only strengthens team spirit but also leads to more effective results.

5. Value Stream Mapping (VSM)

Value Stream Mapping is a method for visualizing the value chain.

Analyze the various steps in your process and identify processes that do not deliver real value. Eliminate these steps to increase efficiency in your workflow.

Summary

The five Lean Tools you have learned about here are not only easy to apply but also provide an excellent foundation for continuous improvement. Whether 5S, TPM, SFM, Problem Solving, or Value Stream Mapping – all these tools contribute to optimizing your processes.

Frequently Asked Questions

How often should I apply the 5S method?The 5S method should be applied regularly to ensure sustainable improvement.

What is the main purpose of TPM?TPM aims to avoid downtime and enable continuous improvement in processes.

How can I establish SFM in the company?Organize regular meetings and workshops to promote communication between employees and managers.

What is meant by a Problem Solving Culture?It is an environment where employees are actively encouraged to identify problems independently and find solutions.

How does Value Stream Mapping work?It visualizes the value chain to identify and eliminate inefficient processes.