Lean project management is more than just a catchphrase - it's a philosophy that increases the efficiency of projects and conserves valuable resources. To understand the methods and benefits of the Lean approach, let's take a closer look at what exactly lies behind this concept and how you can effectively implement it in your projects.

Key Insights

- Lean means "lean" and refers to the minimization of waste in projects.

- The focus is on customer benefit and value creation.

- There are three types of waste processes: Muda (waste), Mura (unevenness), and Muri (overload).

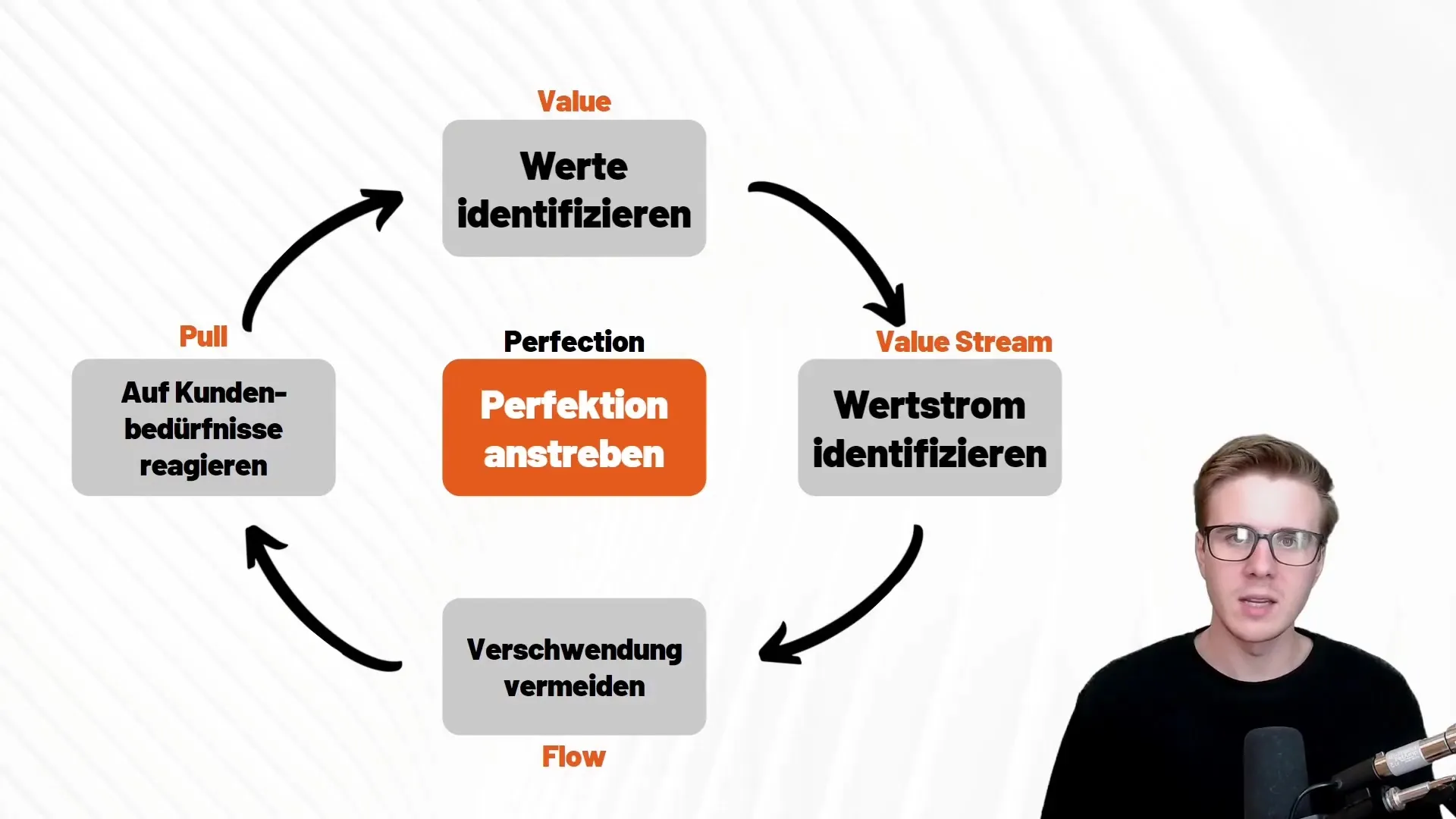

- The cornerstones of Lean management are identifying values, analyzing the value stream, minimizing waste, and following the pull approach.

Step-by-Step Guide

1. Understanding Lean Project Management

To grasp the basics of Lean project management, it's important to understand that it is a method focused on optimizing processes. The approach aims to eliminate everything unnecessary while keeping the customer's value at the forefront. In Lean projects, the term "lean" is used, which means "slim." It's about designing processes to consume as few resources as possible without compromising on product quality.

2. The Principles of Lean

Lean project management is based on five fundamental principles. At the core is customer benefit: What is important to the customer? When and how does he need the product or service? Marketing plays a key role here as it needs to identify customer needs to pinpoint the right values.

3. Identifying Types of Waste

To understand waste, it's crucial to know the three main types that play a role in Lean projects: Muda, Mura, and Muri.

- Muda: This is the waste of resources, time, or materials that do not directly benefit the customer. Examples include unnecessary waiting times or redundant work.

- Mura: It refers to irregularities in the process flow leading to uncertainties and inefficiencies. This can arise when tasks are not equally distributed.

- Muri: This is overburden, whether of employees or machines, leading to errors and inefficient workflows.

4. Customer Analysis for Value Determination

Before starting a project, a thorough analysis of customer needs is necessary. The goal is to identify the relevant features and functionalities important to the customer. In this step, you should ask questions like: What is crucial for my customer? Which features lead to real added value?

5. Conducting Value Stream Analysis

Now that you know your customers' needs, you should conduct a value stream analysis. This means examining each step in the process and analyzing how value is created. You can identify bottlenecks or redundant processes that can be eliminated in this process.

6. Minimizing Waste

The next step involves overseeing established value stream processes and deliberately eliminating waste. This also means looking at which steps in the workflow consume time or resources without adding value. You want to ensure that each process step is necessary and contributes to the overall result.

7. Introducing the Pull Principle

The pull principle dictates that production and services should only be provided when there is actually a demand. You should ensure that your processes are designed to flexibly respond to market needs. By organizing production according to the pull principle, you ensure that your resources are efficiently utilized.

8. Striving for Perfection

The goal of Lean project management is to build a culture of continuous improvement. It's crucial to constantly question your work and results, placing efforts towards perfection at the forefront. Practical approaches include regular feedback and adjustments along the value stream.

9. Implementation in Practice

Once you are familiar with the Lean principles and understand their significance, it is time to implement them in your projects. Start with small steps and monitor the implementations carefully. It is important to gather feedback from your team and stakeholders in order to make gradual adjustments and optimize the strategies.

Summary

Lean project management is a brilliant method to maximize efficiency, customer value, and product quality. By identifying values, conducting value stream analysis, and minimizing waste, you not only achieve better results but also increase customer satisfaction.

Frequently Asked Questions

What is Lean Project Management?Lean project management is an approach to minimize waste and maximize customer value.

What types of waste exist?There are three main types of waste: Muda (waste), Mura (unevenness), and Muri (overburden).

How do I identify value for the customer?By conducting thorough market analyses and collecting customer needs, you can understand what is important to your customers.

How can I avoid waste?By analyzing value streams, you can identify and eliminate inefficient steps.

What is the Pull approach?The Pull approach means that services and products are only produced when there is a demand.